Li-rabara tse tšehelitsoeng le lilara tse kopaneng tsa ceramic

-

Lisebelisoa tsa lipeipi tse nang le matsoho a ceramic tse sebelisoang indastering ea merafo

Sekoahelo se seholo sa ceramic sa bophara se lula e le bothata bo boholo bakeng sa baetsi ba li-tube tsa ceramic kaha ho thata haholo ho laola sekhahla sa deformation ea sleeve ea ceramic ka mor'a hore e sintering .Hape E tla boela e hloke mochine o tsoetseng pele le o moholo oa isostatic ho etsa sena .So it. e ke ke ea hlahisa feela bokhoni ba tlhahiso ea k'hamphani, empa theknoloji ea k'hamphani.Hona joale, fektheri ea rona e na le melemo ka bobeli e leng lisebelisoa tsa ho hatella tsa ceramic le theknoloji.

-

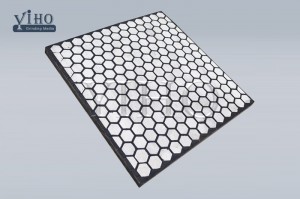

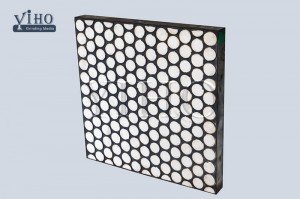

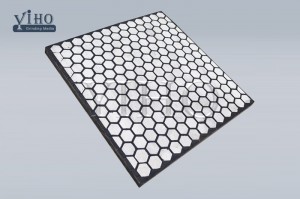

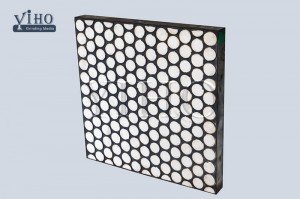

TŠIRELETSO EA BOHLOKOA TŠEBELETSO EA LITŠOANTŠISO TSA KHETHO EA LIREMIKE/Rabara

Ceramic composite rabara e tšehelitsoeng poleiti ea tšepe ke lesela le senyang ceramic le rabara ka har'a poleiti ea tšepe.E ka kopanngoa le liboutu le linate kapa ka ho tjheseletsa poleiti ea tšepe ho etsa likhokahanyo.Hangata sehlahisoa sena ke lihlahisoa tse hlophisitsoeng, li ka etsoa ka libopeho tse fapaneng, botenya bo fapaneng ho ea ka maemo a ho sebetsa.

-

Li-hoses tsa rabara tse tenyetsehang tse nang le ceramic lined

Lithaele tsa Ceramic kapa Libolo tsa Ceramic li kenngoa ka har'a tube e ka hare ea Performer Ceramic Hose.Thepa ea ceramic e khethiloe bakeng sa khanyetso ea eona e ntle ea abrasion mme e lumella bonyane linako tse 10 nako e telele ea bophelo ha e bapisoa le hose ea rabara.

-

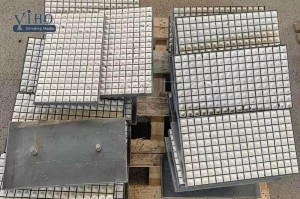

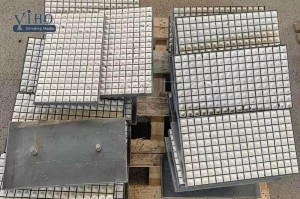

2 in1 kapa 3 ho 1 Composite Ceramic Wear Plate

Letlapa le entsoeng ka rabara ea ceramic e kopantsoeng.

Khanyetso e ntle ea ho roala, bophelo ba ho roala ha alumina ceramic e phahameng ke hoo e ka bang.5 nako e telele ho feta rabara le makhetlo a 10 ho feta tšepe.

Li-cushions tsa rabara kapa tsa polyurethane li hana tšusumetso ho feta, li etsa hore li se ke tsa hlola li ba le tšusumetso.

E fumaneha ka libopeho le boholo bo sa tloaelehang.

-

Lipoleiti tsa ho roala ka ceramic bakeng sa abrasion e mabifi

Plate ea ho roala ka ceramic e sebelisoa libakeng tse mabifi e le kannete moo phallo e boima ea thepa e mahoashe e bakang tšusumetso le khatello ea thepa.Letlapa la ho roala ka ceramic le kenya letsoho ho ntlafatseng ho haneloa ha abrasion, mojaro o phahameng oa moputso le bophelo bo bolelele ba ts'ebeletso.

-

RUBBER-CERAMIC ARE LINES

Bongata ba li-liner tsa rona li etselitsoe ho sebelisoa femeng ea tšebetso, ho fehla motlakase le liindasteri tsa ho sebetsana le thepa.Ho roala lisebelisoa tse sebelisoang li kenyelletsa lira tsa ceramic, li-composites tsa ceramic, lipoleiti tsa ho roala rabara tse kenyelletsang li-mill mill le liner har'a tse ling tse ngata, li-basalt linings, li-epoxy wear compounds.

litharollo tsa liner li sireletsa lisebelisoa tsa hau tse sebetsanang le li-chute, meqomo le litanka le ho ntlafatsa phallo ea thepa ka semela sa hau.Lihlopha tsa rona tsa ho kenya li kenya li-liner tsa hau ka botlalo 'me li fana ka thuso le/kapa tlhokomelo ha ho hlokahala.

-

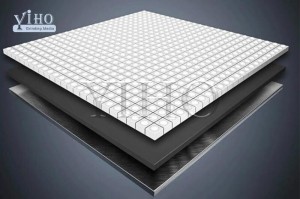

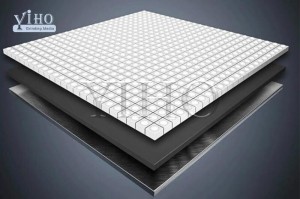

Apara lipoleiti tsa ceramic tse hlenneng ka tšepe tsa rabara-ceramic

Litšebelisong tse matla tsa indasteri, lisebelisoa tse nang le tšusumetso e matla, ho khoahlaha holimo haholo ho ka hlaseloa ke ts'ebetso, tlhaselo ea lik'hemik'hale, ho bola, kapa ka ho kopana ha mekhoa ena e meraro.

YIHO's Ceramics e ka fana ka poleiti ea liner ea ceramic e fapaneng bakeng sa tikoloho ea bareki.Composite ceramic wear liner e etselitsoe lisebelisoa tse thata ka ho fetisisa tse nang le thepa e phahameng haholo.ha motsoako oa ho apara ka mokhoa o feteletseng le ho hanyetsa ha ho ntse ho hlokahala nako e telele ea ho apara, Ultraming e fana ka liner tse entsoeng ka ceramic tse nang le litene tse kholo le tse thata tse entsoeng ka vulcanized ho kena ka har'a matrix ea ho roala rabara e sa thibeleng.E etsa hore ho khonehe ho sebelisa sehlahisoa sena lits'ebetsong tse nang le tšusumetso e ngata ntle le kotsi ea ho senya litene tsa ceramic .

-

CERAMIC CLINDER BAKENG SA TŠIRELETSO E FETILENG EA SEBELE

Lisebelisoa tsa Mineral Processing li sebetsa libakeng tse ling tse thata le tse hole.Ho bohlokoa ho indasteri ea Ts'ebetso ea Liminerale hore lisebelisoa tsena li tsoelepele ho sebetsa ka nepo le hore potoloho ea bophelo ba eona e eketsoe ho fokotsa nako ea ho theoha.Ka ho sireletsa lisebelisoa ka mokhoa o nepahetseng ho tloha ho apara ho feteletseng ho bakoang ke lebelo le phahameng le ho phalla ha ore ha ho sebetsoa e le slurry ho tiisa hore lisebelisoa li phela nako e telele.Slurry e senya haholo 'me e ke ke ea baka tšenyo ea moaparo feela ho lisebelisoa tsa ho sebetsa tse metsi empa hape ka ho kenyelletsa lik'hemik'hale le mocheso, ho na le kotsi e sa khaotseng ea ho senya le ho lutla ho kotsi.

-

Abrasion & Anti impact Ceramic Skirting Canoe Liners

Ho boloka sehlahisoa se le moleng le kantle ho litselana le lisebelisoa tse haufi ho bohlokoa ho boloka tikoloho ea mosebetsi e bolokehileng le e behang litholoana.Li-skirting liner tsa rona tse thata li fumaneha ka rabara e tiileng kapa motsoako oa rabara / ceramic matrix, liaparo tsa rona tse phahameng tse apereng li-skirt li boloka ore le ho sireletsa lisebelisoa tsa hau, ho boloka nako le chelete ha li ntse li eketsa tlhahiso.Handy Tee slot mounting e lumella ho sebelisoa ho skirting kapa lisebelisoa tse tiileng tsa ho roala leboteng 'me lia fetoha.

-

Letlapa la tšepe la ceramic le hlolehang ho apara

Sekhomaretsi sa tšepe sa Wear-resistant ceramic bonding se tlamahanya ka kotloloho sekhomaretsi se thata sa tlhaho kapa sekhomaretsi sa inorganic se nang le mocheso o phahameng oa 350 ℃ ka har'a poleiti ea tšepe, 'me se sebelisoa e le sethibela ho apara. lesela bakeng sa thepa e tsamaisang thepa libakeng tsa mocheso oa kamore.