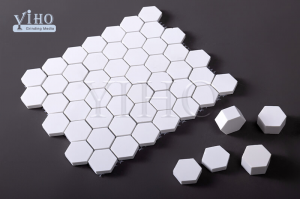

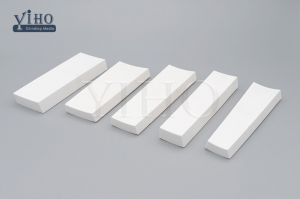

Lipoleiti tsa ho roala ka ceramic bakeng sa abrasion e mabifi

Apara lipoleiti bakeng sa tikoloho e boima

Letlapa la li-ceramic le na le khanyetso e phahameng haholo ea ho khoholeha ha mochini le khoholeho ea mobu.Li sebelisoa ka molemo e le thepa ea kaho libakeng tsa lithōle tsa literaka le likepeng tse laelang le ho theola lehlohlojane le mafika a chekiloeng, bakeng sa ho sebetsana le maqeba a tšepe a boima le mosebetsing oa ho heletsa moo konkreite e nang le litšepe tse matlafatsang e lokolloang holim'a bethe e bataletseng.

Boemo bo tlase ba lerata

Li-ceramics tsa lipoleiti li kenngoa ka foreime ea tšepe kapa li kenngoe ka har'a rabara, e leng se eketsang ho hanyetsa tšusumetso le ho fokotsa boemo ba lerata ka lebaka la thepa ea rabara e monyang ho sisinyeha.Li ka kenngoa ka bolt kapa tsa khomareloa ka ho toba holim'a sejana sa ho roala.

Ho hlahisa ho ya ka tlhophiso

Yiho e lula e fana ka tharollo e ntlafalitsoeng moo lipoleiti tsa rona tsa ceramic li hlahisoang ho latela litlhaloso tsa bareki.Ho ela hloko, har'a lintho tse ling, ts'ebeliso le phallo ea thepa, mofuta oa ceramic, litekanyo le botenya, ka ho kenya rabara kapa ntle le eona, joalo-joalo.

Lintho tsa Ceramic: Silicon Carbide

Silicon Carbide (SiC)

Silicon carbide e thehoa ka litsela tse peli, ho kopanya karabelo le sintering.Mokhoa o mong le o mong oa ho etsa o ama haholo sebopeho sa microstructure.

Reaction bonded SiC e entsoe ka ho kenella ka likhoka tse entsoeng ka metsoako ea SiC le k'habone e nang le silicon e metsi.Silicon e sebetsana le carbon e etsang SiC e eketsehileng e kopanyang likaroloana tsa pele tsa SiC.

Sintered SiC e hlahisoa ho tsoa ho phofo ea SiC e hloekileng e nang le lithuso tsa sintering tse seng oxide.Ho sebelisoa mekhoa e tloaelehileng ea ho etsa ceramic, 'me thepa e tšeloa ka har'a sepakapaka se sa keneleng mocheso ho fihlela ho 2000ºC kapa ho feta.

Mefuta e 'meli ea silicon carbide (SiC) e sebetsa ka thata haholo ka thepa e ntle ea mochini, ho kenyelletsa matla a mocheso o phahameng le ho hanyetsa mocheso oa mocheso.Baenjiniere ba rona ba lula ba le teng ho u eletsa hantle ka matla le mefokolo ea ceramic ka 'ngoe bakeng sa litlhoko tsa hau tse ikhethang.

Litšobotsi tse tloaelehileng tsa silicon carbide li kenyelletsa:

• Boima bo tlaase

• Matla a phahameng

• Matla a matle a mocheso o phahameng (a tlamehile ho arabela)

• Oxidation resistance (rection bonded)

• Ho hanyetsa mocheso o babatsehang oa mocheso

• Boima bo phahameng le ho hanyetsa ho apara

• Ho hanyetsa lik'hemik'hale tse babatsehang

• Katoloso e tlase ea mocheso le conductivity e phahameng ea mocheso

Lisebelisoa tse tloaelehileng tsa silicon carbide li kenyelletsa:

• Likarolo tsa turbine tse tsitsitseng le tse tsamaeang

• Litiiso, li-bearings, li-vane tsa pompo

• Likarolo tsa li-valve tsa bolo

• Apara lipoleiti

• Fetola thepa ea ka tlung

• Lisebelisoa tsa mocheso

• Thepa e sebetsanang le semiconductor wafer

Ho fumana lintlha tse ling mabapi le silicon carbide ea rona le hore na sena se ka sebelisoa joang bakeng sa sehlahisoa sa hau, ikopanye le rona kajeno