Lisebelisoa tsa lipeipi tse nang le matsoho a ceramic tse sebelisoang indastering ea merafo

Mabapi le lisebelisoa tsa liphaephe tse entsoeng ka letsoho la ceramic

Sekoahelo se seholo sa ceramic sa bophara se lula e le bothata bo boholo bakeng sa baetsi ba li-tube tsa ceramic kaha ho thata haholo ho laola sekhahla sa deformation ea sleeve ea ceramic ka mor'a hore e sintering .Hape E tla boela e hloke mochine o tsoetseng pele le o moholo oa isostatic ho etsa sena .So it. e ke ke ea hlahisa feela bokhoni ba tlhahiso ea k'hamphani, empa theknoloji ea k'hamphani.Hona joale, fektheri ea rona e na le melemo ka bobeli e leng lisebelisoa tsa ho hatella tsa ceramic le theknoloji.

Re ile ra kopana le mathata a mang ha re etsa li-sleeve tsa ceramic 'me ra sebetsana le mathata ohle ka mor'a boiteko ba batho ba rona ba lipatlisiso le boenjiniere kholo le boima .Ka mor'a ho sebetsa khoeli , re qetile sena 20' setshelo 95% alumina ceramic sleeve lined liphaephe ,T liphaephe le litsoele le bareki ba boetse ba ananela haholo ka karabelo ea rona e potlakileng le boiteko bo boholo mererong ena e sebelisoang tsamaisong ea merafo ea slurry transveying. .

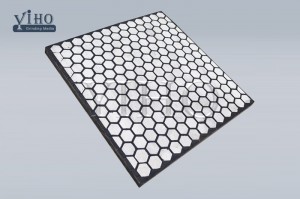

Sintering e le tube eohle ea ceramic kapa sleeve ea ceramic, ebe o e kopanya ka har'a phala ea tšepe kapa phala ea tšepe e sa hloekang ka sekhomaretsi sa rona sa epoxy se sa keneleng mocheso o phahameng.Peipi e kentsoeng ka letsoho la ceramic e sebelisitse haholo indastering ea merafo, joalo ka phala ea slurry ea merafo, peipi e tlosang lerōle la merafong, peipi e fetisang merafo, libono le lipeipi tsa T.

Mofuta ona oa phala e entsoeng ka lithaelese tsa ceramic e na le likarolo tse tharo (peipi ea tšepe + sekhomaretsi + lithaele tsa ceramic), phala ea tšepe e entsoe ka phala ea tšepe ea seamless.Lithaele tsa ceramic ke 95% ea alumina e phahameng, 'me ho tlamahano ke sekhomaretsi se phahameng sa mocheso oa epoxy ho fihlela ho 350oC. Mofuta ona oa pipe o loketse ho tsamaisa phofo ntle le tile e oelang kapa botsofali bo sebetsang tlas'a 350oC ka nako e telele.Nako ea bophelo ba tšebeletso ke makhetlo a 4 ho isa ho a 5 ho feta pipe e tloaelehileng ea tšepe.

Lisebelisoa tsa liphaephe tse nang le matsoho a ceramic Bophahamo ba ts'ebeliso

Liphaephe tsena tse sebelisetsoang Pneumatic and Hydraulic Systems li na le ts'oaetso e phahameng, ho thella ho phahameng le tšusumetso e phahameng, haholo-holo bakeng sa litsoe.Re ka boela ra rala lisebelisoa tsa liphaephe tse tloaelehileng ho kopana le mekhoa e fapaneng ea ho sebetsa.

Ceramic Wear Tile Material & Linepe

-92% Alumina

-95% Alumina

-99% Alumina

-RBSiC Silicon carbide

- Sesebelisoa sa ZTA

| Sehlopha | HC92 | HC95 | HCT95 | HC99 | HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Botenya (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 |

| HV20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| Lefika le thata HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Matla a Kobang MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Matla a ho hatella MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Ho Toughness ea Fracture (KIc MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Bolumo ea ho roala (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 |