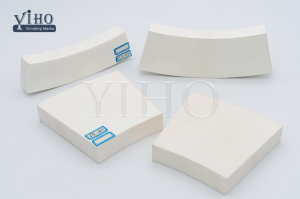

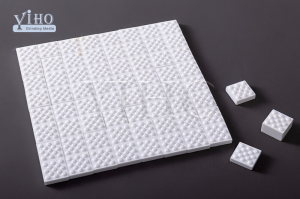

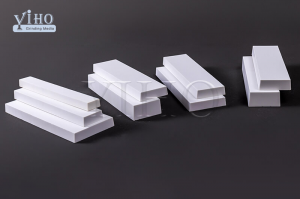

Meepo ea Mashala Ceramic Perforated Lining Plate Weldable Tile

Ceramic Perforated Lining Plate Kenyelletso ea Tile e Weldable

YIHO e fana le ho kenya mefuta e mengata ea Alumina Wear Resistant Tiles bakeng sa tšireletso ea ho apara libakeng tsohle tse kang Chutes, Silos, Feeders, Bins, Launders, Dutching, Tanks, Bunkers, Hoppers, Underpans joalo-joalo.

Alumina ceramics e hlalosoang e le thepa ea kamoso, ke e 'ngoe ea lintho tsa tlhaho tse thata ka ho fetisisa tse tsejoang ke motho.Tlas'a maemo a hlabang haholo, ha ho na thepa e ka qothisanang lehlokoa le litšenyehelo tsa bophelo ka boima ba eona bo feteletseng le ho se mamelle.Ntle le moo, li-ceramics tsa alumina li na le lisebelisoa tse ikhethang tsa lik'hemik'hale, tsa mochini, tse futhumatsang le tsa motlakase 'me li ka etsoa ka sebopeho kapa boholo bo nang le litšobotsi tse fapaneng bakeng sa lits'ebetso tse ikhethileng.

Lithaele tsa Weld-On alumina ceramic hangata li sebelisoa lits'ebetsong tsa mocheso o phahameng 'me li fumaneha ka boholo bo bongata ho lumellana le kopo ea hau ho latela thepa ea khale.

Ceramic Perforated Lining Plate Weldable Tile Technical Data

| Sehlopha | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | ≥21% | ≥95% |

| Botenya (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 | >5.90 |

| HV20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Lefika le thata HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Matla a Kobang MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Matla a ho hatella MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Ho Toughness ea Fracture (KIc MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Bolumo ea ho roala (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 | ≤0.02 |

Ceramic Perforated Lining Plate Weldable Tile Melemo

Lithaele tsa aluminium tse chesehang, tse tsejoang hape e le lithaelese tsa alumina ceramic weld-on kapa lithapo tse chesehang tsa ceramic, li fana ka melemo e mengata ha li sebelisoa lits'ebetsong tse sa tsitsang.Lithaele tsena hangata li sebelisoa ho sireletsa lisebelisoa tsa indasteri le bokaholimo ho tsoa ho abrasion, ts'usumetso le ho khathala.Mona ke tse ling tsa melemo ea bohlokoa ea lithaelese tse chesehang tsa alumina:

1. Boima bo phahameng le ho hanyetsa ho roala: Alumina ceramic ke e 'ngoe ea lisebelisoa tse thata ka ho fetisisa, tse fanang ka ho hanyetsa ho apara hantle le ho tšoarella.Lithaele tse chesehang tse entsoeng ka alumina li nepahetse bakeng sa ho sireletsa lisebelisoa le bokaholimo bo pepesehileng lisebelisoa tse hohlang.

2. Khanyetso ea Lik'hemik'hale le Corrosion: Alumina ha e na lik'hemik'hale 'me e hanyetsa haholo lintho tse senyang, e leng se etsang hore e loketse ho sebelisoa liindasteri tse nang le lik'hemik'hale tse mabifi.

3. Ho hanyetsa Mocheso: Lithaele tse chesehang tsa Alumina li ka mamella mocheso o phahameng ntle le ho senyeha ho hoholo ha thepa ea tsona, e leng ho etsang hore li tšoanelehe bakeng sa lits'ebetso tse amanang le mocheso o phahameng kapa mocheso oa mocheso.

4. Sekaho se Seng se Tšoanang: Lithaele li fana ka sebaka se boreleli le se ts'oanang, se fokotsa ho hahoa ha thepa le ho netefatsa hore thepa e phallang ka mokhoa o tsitsitseng, e leng ea bohlokoa bakeng sa mekhoa e itseng ea indasteri.

5. Ho Eketsoa habonolo: Joalokaha lebitso le fana ka maikutlo, lithaele tse chesehang li etselitsoe ho kenya habonolo ho sebelisa mekhoa ea ho tjheseletsa.Sena se lumella ho khomarela ka potlako le ka mokhoa o sireletsehileng ho substrate, ho fokotsa nako ea ho phomola nakong ea ho kenya le ho lokisa.

6. Libopeho le boholo bo ka tloahelehang: Lithaele tse chesehang tsa Alumina li ka etsoa ka libopeho le boholo bo fapaneng ho lumellana le lisebelisoa tse khethehileng kapa libaka, ho fana ka ho feto-fetoha ha moralo le ho netefatsa tšireletso e feletseng ea libaka tse tloaelehileng.

7. Nako e Fokotseng ea Tlhokomelo: Ka ho sireletsa thepa ea motheo ho tloha ho senya le ho senya, lithaelese tsa alumina weldable li eketsa bophelo ba ts'ebetso ea lisebelisoa, ho fokotsa nako ea ho boloka le ho fokotsa nako.

8. Theko e Ntle: Le hoja lithaele tsa alumina tse chesehang li ka ba le litšenyehelo tse phahameng tsa pele ha li bapisoa le lisebelisoa tse ling, nako e telele ea bophelo ba tsona le litlhoko tse fokotsehileng tsa tlhokomelo li etsa hore li be le chelete e ngata ha nako e ntse e ea.

9. Motlakase oa Motlakase: Alumina ke insulator e babatsehang ea motlakase, e etsang hore e tšoanelehe bakeng sa lisebelisoa moo motlakase oa motlakase o lokelang ho qojoa.

10. Ho Ikamahanya le Li-substrates tse fapaneng: Lithaele tse chesehang tsa Alumina li ka sebelisoa ho li-substrates tse fapaneng, ho kenyeletsoa tšepe, konkreite le lisebelisoa tse ling, li etsa hore li feto-fetohe bakeng sa lits'ebetso tse fapaneng tsa indasteri.

Ka kakaretso, lithaelese tse chesehang tsa alumina li fana ka tharollo e tšepahalang le e sebetsang bakeng sa lits'ebetso tse manganga, tse fanang ka tšireletso khahlano le abrasion, tšusumetso le tlhaselo ea lik'hemik'hale.Ho tšoarella ha bona, boiketlo ba ho kenya, le ho boloka litšenyehelo ka nako e telele ho etsa hore e be khetho e ratoang liindastering tse kang tsa merafo, samente, tšepe, tlhahiso ea matla le ho sebetsana le thepa, moo ho senyeha ho tloaelehileng ho leng thata.