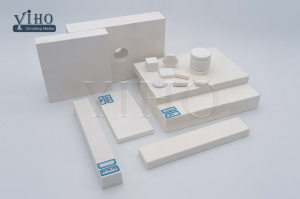

Abrasion & lmpact resistant Ceramic Wear Linings

-

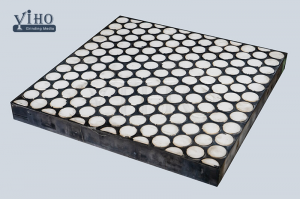

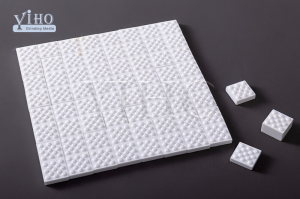

Boenjiniere Apara Ceramic Matrix

Abrasion e lula e ke ke ea qojoa ts'ebetsong le ho tsamaisa thepa e ngata.Phallo ea thepa e oelang e baka tšusumetso e matla haholo.Re fa bareki ba rona litharollo tse ntle ka ho fetisisa tsa boleng bo holimo ba ceramic wear matrix (e nang le / ntle le poleiti ea tšepe le bolt), e le ho fihlela sephetho se nepahetseng ho eketsa ts'ebetso ea ho hanyetsa le ho fokotsa lerata le lerata.

-

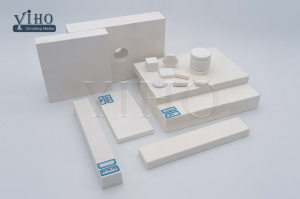

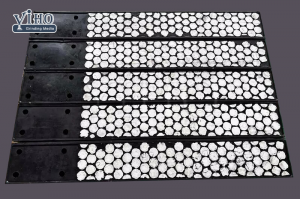

Letlapa le omisitsoeng la Alumina Wear

Li-Wear Plates li entsoe le ho etsoa bakeng sa ts'ebeliso ea tsona e ikhethileng, ho netefatsa hore poleiti e nepahetseng e lula e khothaletsoa ebile e kentsoe.

-

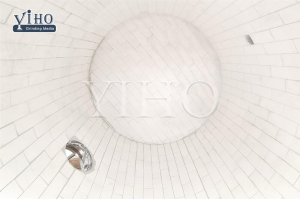

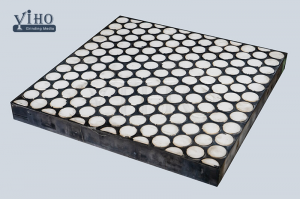

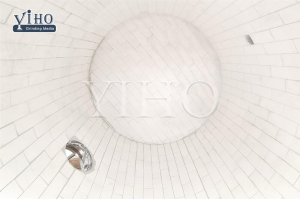

Moetsi ea Direct oa 92% le 95% Al2O3 ceramic lening ball mill setene

Yiho e sebelisa boleng bo holimo, lijo-thollo tse 92% / 95% setene sa alumina ka leleme le moralo oa groove.Litene li sirelelitsoe 'me li entsoe ka samente e hloekileng ea Portland kapa epoxy ea likarolo tse peli.Ha e le nako ea ho reline leloala hape ke nako e ntle ea ho hlahloba likarolo tsa li-bearings le ho khanna.

-

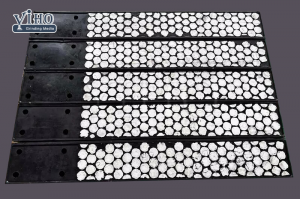

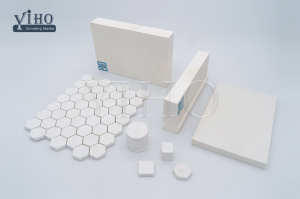

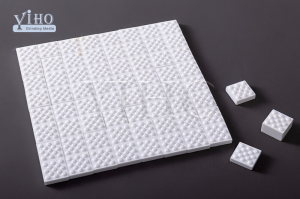

Lithaele tsa Ceramic Wear tse tšoarellang ka nako e phahameng bakeng sa Keketseho ea ho hanyetsa ho apara

YIHO e fana ka mefuta e fapaneng ea libopeho le lithaelese tsa ceramic tse boholo bo boholo bakeng sa lits'ebetso tsa hau tse matla tsa ho roala.YIHO e ka fana ka lithaele tsa boholo bo tloaelehileng (lisekoere le khutlonnetsepa), lithaele tsa hex hammoho le libopeho le boholo ba tloaelo bakeng sa ts'ebeliso ea hau e boima.

-

Conveyor Chute Lining Impact Liner Panel

Chute Linings e etselitsoe ho ba karolo ea bohlokoa ea sistimi e tsamaisang thepa.Lesela la rona la li-chute le entsoeng esale pele le sireletsa le ho koala chute ho thepa e tšoaroang;Li-Skirt Liners li thibela lisebelisoa tse balehang ho baleha le ho senya libaka tsa ho laela tse tsamaisang thepa.Re ka haha, ra rala, ra etsa le ho kenya li-chute, hape ra lokisa le ho hokahanya lithako tse teng hape.

-

Meepo ea Mashala Ceramic Perforated Lining Plate Weldable Tile

YIHO e fana le ho kenya mefuta e mengata ea Alumina Wear Resistant Tiles bakeng sa tšireletso ea ho apara libakeng tsohle tse kang Chutes, Silos, Feeders, Bins, Launders, Dutching, Tanks, Bunkers, Hoppers, Underpans joalo-joalo.

-

Chute ceramic Tile wear liner

Lipoleiti tsa tšepe tse tšehelitsoeng ka ceramic li chesa li chesoa hammoho le lakane ea rabara e matla ea tlhaho le poleiti e tšehelitsoeng ea tšepe ea 3 ~ 10mm.Ka lebaka leo, li-ceramics wear liner li tla ba le melemo e 'meli ea ho hanyetsa tšusumetso ea rabara le khanyetso ea ho apara ka ceramic.

-

Lisebelisoa tsa lipeipi tse nang le matsoho a ceramic tse sebelisoang indastering ea merafo

Sekoahelo se seholo sa ceramic sa bophara se lula e le bothata bo boholo bakeng sa baetsi ba li-tube tsa ceramic kaha ho thata haholo ho laola sekhahla sa deformation ea sleeve ea ceramic ka mor'a hore e sintering .Hape E tla boela e hloke mochine o tsoetseng pele le o moholo oa isostatic ho etsa sena .So it. e ke ke ea hlahisa feela bokhoni ba tlhahiso ea k'hamphani, empa theknoloji ea k'hamphani.Hona joale, fektheri ea rona e na le melemo ka bobeli e leng lisebelisoa tsa ho hatella tsa ceramic le theknoloji.

-

TŠIRELETSO EA BOHLOKOA TŠEBELETSO EA LITŠOANTŠISO TSA KHETHO EA LIREMIKE/Rabara

Ceramic composite rabara e tšehelitsoeng poleiti ea tšepe ke lesela le senyang ceramic le rabara ka har'a poleiti ea tšepe.E ka kopanngoa le liboutu le linate kapa ka ho tjheseletsa poleiti ea tšepe ho etsa likhokahanyo.Hangata sehlahisoa sena ke lihlahisoa tse hlophisitsoeng, li ka etsoa ka libopeho tse fapaneng, botenya bo fapaneng ho ea ka maemo a ho sebetsa.

-

Li-hoses tsa rabara tse tenyetsehang tse nang le ceramic lined

Lithaele tsa Ceramic kapa Libolo tsa Ceramic li kenngoa ka har'a tube e ka hare ea Performer Ceramic Hose.Thepa ea ceramic e khethiloe bakeng sa khanyetso ea eona e ntle ea abrasion mme e lumella bonyane linako tse 10 nako e telele ea bophelo ha e bapisoa le hose ea rabara.

-

Lithaele tsa Ceramic pulley tse salang

Ceramic pulley lagging ke tharollo e ka tšeptjoang bakeng sa mathata a ho thella ha lebanta, hoo hangata ho sa khoneheng ho lokisa rabara e tloaelehileng.Ebile, e na le khohlano e phahameng ka ho fetesisa e fumanehang linthong tse salletseng morao tse ka bang makhetlo a mabeli ho isa ho a mararo ho khohlano ea rabara maemong a mongobo, a seretse kapa a omileng.YihoCeramic pulley lagging e hahiloe ho tsoa ho batho ba makhololithaele tsa ceramice bopehileng ka ho tshehetso ya rabara e tšoarellang.

-

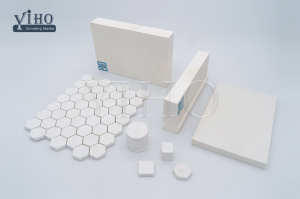

Ceramic Hexagonal roa limmete tsa lithaele

YIHO e etsa mefuta e mengata e felletseng ea lithaelese tsa hex (lithaele tse hexagonal) tse sa jeleng paate.Alumina ea rona ea ceramic e haufi le daemane ka thatafala, e mamella makhetlo a 12 ho feta tšepe ea carbon, 'me e bonts'a khanyetso e ntle ea kutu.