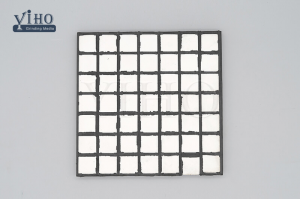

Hybrid Liner Rabara Ceramic Matrix

MABAPI LE Hybrid Liner Rubber Ceramic Matrix

E kopantsoe ka mokhoa o khethehileng, Hybrid Liner e kopanya lisebelisoa tse peli tsa liner le thepa ea tsona e ntle.Bokahare bo entsoe ka polyurethane 'me e sireletsa karolo e setseng ea maoto le masapo ka lebaka la litšobotsi tsa eona tse monyang maikutlo.Ka nako e ts'oanang, e netefatsa phallo e nepahetseng ea khatello ho pholletsa le leoto lohle le setseng, bakeng sa tlhahiso e sa sebetseng le e sebetsang ea vacuum.Bokantle ba liner le vacuum flap e kopantsoeng e entsoe ka silicone, e pakoang ts'ebelisong ea letsatsi le letsatsi ka lebaka la ho tiea ha eona.Sena se bohlokoa ka ho khetheha ha sekoti sa vacuum se phuthoa holim'a sokete e ka hare ho etsa tiiso e sa keneng moea bakeng sa sistimi.

Hybrid Liner Rubber Ceramic Matrix Application

Tabeng ea abrasion mabapi le li-rabara tsa rabara, lipolelo tse latelang li tlameha ho nkoa.

1- Ho na le mefuta e 'meli ea abrasion eo motho a ka kopanang le eona, ho kenella le ho thella.

2- Impingement abrasion e etsahala ha likaroloana li otla bokaholimo ba rabara (kapa bokaholimo bofe kapa bofe).

3- Sliding abrasion e etsahala ha bokaholimo bo bong bo thella ho rabara.

4- Hoo e batlang e le ketsahalong e 'ngoe le e' ngoe ho ka lebelloa hore ho senya ho ka ba motsoako oa ho kenya letsoho le ho thella.

5- Haholo-holo abrasion ea ho kenya letsoho e etsahala ka har'a li-chute, hose ea sandblast mme kae kapa kae ho bonoa.

6- Ts'ebetsong ea ho kenya letsoho, likaroloana li otla holimo 'me likhatello leha e le life tse hlahisoang li ajoa ka mokhoa o lekanang haeba rabara e hlahisa habonolo, haholo-holo ha likaroloana li otla ka lehlakoreng la 90 ° holimo.

Lisebelisoa tsa Ceramic (Alumina + Reaction Bonded Silicon Carbide Tiles)

| Sehlopha | 92% Al2O3 | 95% Al2O3 |

| ZrO2 | / | / |

| Botenya(gr/cm3) | >3.60 | >3.65g |

| HV20 | ≥950 | ≥1000 |

| Lefika le thata HRA | ≥82 | ≥85 |

| Matla a Kobang MPa | ≥220 | ≥250 |

| Matla a ho hatella MPa | ≥1050 | ≥1300 |

| Ho Toughness ea Fracture (KIc MPam 1/2) | ≥3.7 | ≥3.8 |

| Bolumo ea ho roala (cm3) | ≤0.25 | ≤0.20 |

| Silicon CarbideLintlha(RBSiC) | ||

| Index | Boleng | Sephetho sa teko |

| Sic | / | ≧90 |

| Mocheso | ℃ | 1380 |

| Tekano e Itseng | g/cm3 | ≧3.02 |

| Open Porosity | % | <0.1 |

| Modulus ea elasticity: | GPA | 330Gpa (20 ℃) 300Gpa(1200 ℃) |

| Bothata ba Moh | / | 9.6 |

| Matla a kobehang | Mpa | 250(20℃)/ 280 (1200℃) |

| Matla a Khatello | Mpa | 1150 |

| Coefficient ea katoloso ea mocheso: | / | 4.5K^(-3)*10^(-5) |

| Coefficient of thermal conductivity: | W/mk | 45 (1200 ℃) |

| Acid Alkaline - bopaki | / | E kgabane |