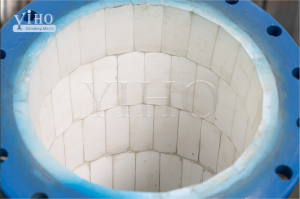

Ceramic Lined Wye Feed Pipe&Tees

Li-pipe wyes le li-pipe tee

Li-pipe wyes li tšoana le li-pipe tee.Phapang e le 'ngoe feela ke hore mohala oa lekala o otlolohile ho fokotsa khohlano e ka sitisang phallo.Khokahano ea liphaephe ka tloaelo e maemong a 45-degree ho fapana le e tloaelehileng ea 90-degree angle.Haeba lekala le qetella le le perpendicular to the through line, pipe fitting e fetoha "tee wye".

Lintho tse ka sehloohong tsa Ceramic

| Sehlopha | HC92 | HC95 | HCT95 |

| Al2O3 | ≥92% | ≥95% | ≥95% |

| ZrO2 | / | / | / |

| Botenya | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 |

| Ho Monyeha ha Metsi | ≤0.1% | ≤0.1% | ≤0.1% |

| HV20 | ≥950 | ≥1000 | ≥1100 |

| Lefika le thata HRA | ≥82 | ≥85 | ≥88 |

| Matla a Kobang MPa | ≥220 | ≥250 | ≥300 |

| Matla a ho hatella MPa | ≥1050 | ≥1300 | ≥1600 |

| Fracture Toughness KIc MPam 1/2 | ≥3.7 | ≥3.8 | ≥4.0 |

| Apara Bolumo | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 |

Litšobotsi phala e entsoeng ka ceramic

Ho hanyetsa ho apara hantle

Pipe e entsoeng ka ceramic ka lebaka la corundum ceramic (a-AL2O3), Mohs hardness ea 9.0 e lekana le ho feta HRC90.Ka hona, e na le khanyetso e phahameng bakeng sa mecha ea litaba ea abrasive e fetisoang ke liindasteri tse kang metallurgy, matla a motlakase, merafo le mashala.E tiisitsoe ke ts'ebetso ea indasteri hore bophelo ba eona ba ho apara bo ka makhetlo a leshome kapa esita le makhetlo a 'maloa ho feta a tšepe e thata.

Khanyetso e nyane ea ts'ebetso

Pipe e kopantsoeng ea SHS ceramic ha e tšoane le khoele e kobehang ka har'a bokahare ba phala ea tšepe e se nang moroko hobane bokaholimo bo ka hare bo boreleli 'me ha bo honyehe.Ho ile ha lekoa ka hare ho bokaholimo ba bokaholimo le litšoaneleho tse hlakileng tsa ho hanyetsa metsi tsa likarolo tsa tlhahlobo tse amehang.Boreleli ba bokaholimo bo ka hare bo ne bo le betere ho feta phala leha e le efe ea tšepe.Coefficient e hlakileng ea ho hula e ne e le 0.0193, e neng e le tlase hanyane ho feta peipi e se nang seam.Ka hona, tube e na le litšoaneleho tsa ho hanyetsa tse nyenyane tse mathang 'me e ka fokotsa litšenyehelo tsa ho sebetsa.

Corrosion, anti-scaling

Kaha lera la tšepe la ceramic ke (a-AL2O3), ke tšobotsi e sa nke lehlakore.Ka hona, e hanana le ho bola ha asiti le alkali le metsi a leoatle, hape e na le thepa ea ho thibela sekhahla.

Ho hanyetsa mocheso le ho hanyetsa mocheso

Ka lebaka la corundum ceramic (a-AL2O3), ke mohaho o le mong o tsitsitseng oa kristale.Ka hona, phala e kopantsoeng e ka sebetsa ka mokhoa o tloaelehileng mocheso oa nako e telele oa -50--700 ° C.Lisebelisoa tsa katoloso ea mohala oa 6-8 × 10-6 / 0C, hoo e ka bang 1/2 ea pipe ea tšepe.Boitsebiso bo na le botsitso bo botle ba mocheso.

Litšenyehelo tsa morero li tlaase

Liphaephe tse entsoeng ka ceramic li boima bo bobebe ebile li theko e tlaase.E bobebe ka 50% ho feta tube ea lejoe la lejoe le nang le bophara bo lekanang ba ka hare;e bobebe ka 20-30% ho feta tube ea alloy e sa sebetseng, 'me e na le khanyetso e ntle ea ho apara le ho thibela kutu ka lebaka la nako e telele ea tšebeletso, kahoo e tšehetsa litšenyehelo tsa hanger, litšenyehelo tsa lipalangoang, litefiso tsa ho kenya, le Ho fokotsa litšenyehelo tsa ho sebetsa.Ha ho bapisoa tekanyetso ea morero oa setsi sa moralo le setsi sa kaho le morero oa sebele, litšenyehelo tsa morero li lekana le lejoe la majoe.Ha ho bapisoa le pipe ea alloy e sa sebetseng, litšenyehelo tsa morero li fokotsehile ka hoo e ka bang 20%.

Ho kenya habonolo le kaho

Ka lebaka la boima ba eona bo bobebe le ts'ebetso e ntle ea welding.Ka hona, li-welding, li-flanges, ho kopanya ka potlako, joalo-joalo li ka amoheloa, 'me kaho le ho kenya li loketse,' me litšenyehelo tsa ho kenya li ka fokotsoa.

Kopo

Lithako tsa liphaephe tse entsoeng ka ceramic li ka boela tsa sebelisoa likarolong tsa pompo ea konkreite ka lebaka la melemo ea tsona, haholo-holo boima bo tlaase, bo thusang ho qoba jeme nakong ea ho tsamaisa konkreite.

Kenya sebaka sa phala ea tšepe ea carbon, phala ea tšepe e sa hloekang le SDR

Phallo e phahameng ea lintho tse bonahalang

Lijo tsa magnetite le melapo ea ho ntša metsi

Mohatla o tlase