Apara Lithako tsa Leholiotsoana tse Hanellang tse entsoeng ka Alumina

Tlhaloso e qaqileng

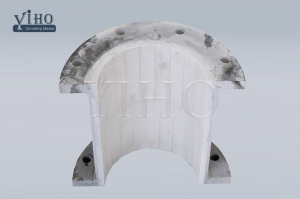

'Mele o ka sehloohong oa leholiotsoana o na le mochini o fokotsang kapa o nang le sebopeho sa khoune se thellang ho tloha bophara bo boholo ho isa ho se senyane ho theosa le bolelele ba sona.

Apara Litharollo tse hanyetsanang bakeng sa Cyclones

Kaha lisebelisoa tse arohaneng le leholiotsoana li senya haholo, ke habohlokoa hore ho be le lesela la leholiotsoana le emang ka thata mosebetsing.Ultra High Purity Alumina e ka sebelisoa ho eketsa bophelo ba ts'ebetso ea leholiotsoana le ts'ebetso mme e ka etsoa ka sebopeho se lumellanang le lijeometri tsohle;ho tloha mosebetsing oa liphaephe tse lebisang ho seketsoana, mochine oa ho fumana vortex le phallo ea holimo, ho ea pelong ea conical ea leholiotsoana.

Likarolo Tsa Leholiotsoana Hangata Li Tla Aroa

Ho na le likarolo tse ngata ka har'a kopano ea leholiotsoana tse tlas'a maemo a phahameng a ho apara.Taylor Ceramic Engineering e ka fana ka tse ngata tsa tsena ka thepa e sa sebetseng ho lelefatsa bophelo ba karolo.Tse ling tsa likarolo tseo re fanang ka tsona hangata li kenyelletsa:

· Cylindrical & Reducing Liners

· Inlets

· Libaka

· Spigots

· Kenya

· Likarolo tsa Khoune e ka Holimo, e Bohareng le e Tlaase

· Ba fumaneng Vortex

· Hoo e batlang e le bokaholimo bofe kapa bofe bo ntseng bo senyeha!

Apara Lifomete tsa Lesela le sa Feleng

Ho ka sebelisoa mefuta e mengata ea mekhoa e sa tsitsang ea lesela;ho tloha ho kenya monolithic ho ea likarolong tse nang le lithaele.

Likarolo tsa Monolithic

YIHO e maemong a ikhethang hore e khone ho etsa libopeho tse nyane le tse kholo tsa monolithic ka liforeimi tsa nako e khuts'oane.Likarolo tsena li ka etsoa ka tloaelo ho lumellana le litlhoko tsa hau tse nepahetseng.

Likarolo tsa monolithic li na le molemo oa hore li potlakile haholo ho kenya, kahoo li fokotsa nako ea ho theoha.

Likarolo tsa Lithaele

Hobane libaka tse ngata tse amanang le kopano ea leholiotsoana li kobehile, Taylor Ceramic Engineering e khona ho etsa lithaelese tse lumellanang le sebopeho se hlokahalang.

Lithaele tse bataletseng libakeng tse kobehileng hangata li siea letoto la lifolete tse pota-potileng bokaholimo ba leholiotsoana.Sena ha se sitise phallo ea thepa feela empa se eketsa moaparo holim'a lithaele mme ka hona se fokotsa bophelo ba lisebelisoa.Leha ho le joalo, ho sebelisa lithaelese tse kobehileng tse ikamahanyang le sebopeho se hlokahalang ho fokotsa li-discontinuities le ho eketsa phallo ea thepa mme ka hona ho sebetsa hantle ha lisebelisoa.

| Sehlopha | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Botenya | ≥3.50g/cm3 | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 | ≥3.83g/cm3 | ≥4.10g/cm3 | ≥5.90g/cm3 |

| Ho Monyeha ha Metsi | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% |

| HV20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Lefika le thata HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Matla a Kobang MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Matla a ho hatella MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Apara Bolumo | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |