Tile ea sekhutlo ea alumina ea pele ho boenjiniere

Selelekela sa lithaele tsa sekhutlo sa alumina tsa pele ho boenjiniere

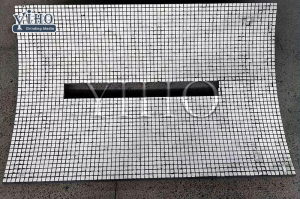

Apara lithaele tsa pele tsa boenjineri tse hanyetsanang ka mefuta e fapaneng ea libopeho tsa geometri ho tloha ho tse bonolo ho isa ho tse rarahaneng, lirafshoa li ka etsoa enjene kapa hlobo ho ea ho libopeho tse ikhethileng ho latela tlhoko ea moreki.

Lisebelisoa tse entsoeng ka ceramic tse kang lipeipi, li-chute, li-hoppers, li-bunkers, joalo-joalo. Alumina ceramic liner e na le khanyetso e ntle ea abrasion, e hanyetsanang ka thata, e hanyetsanang le kutu, e sebelisoa haholo morafong, setsing sa motlakase, setsing sa tšepe, liindasteri tsa samente tse kang li-chute, hopper. ,bunker, leholiotsoana, lebanta le tsamaisang thepa, joalo-joalo. Sehlahisoa sena sa alumina ceramic se etsa hore ho be le ts'ebetso e theko e boima joalo ka ho fokotsa nako le tlhokomelo e sa hlokahaleng, le ho lelefatsa lisebelisoa hore li se ke tsa senyeha kapele.

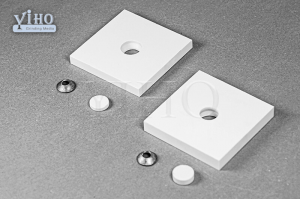

Sehlahisoa sa linings tse entsoeng ka boenjiniere ke se ikhethileng Re ka fana ka le ho kenya mefuta e mengata ea lithaelese tsa alumina ceramic tse entsoeng esale pele tse entsoeng ho lumellana le mofuta ofe kapa ofe oa kopo.Software ea CAD e sebelisetsoa ho rala lesela le sa sebetseng bakeng sa likarolo tsa bareki.Ho sebetsa pele ho sintering ho etsa hore re khone ho fana ka linings tse nang le libopeho tse rarahaneng le tse 3 e le tharollo e theko e tlaase.E tla lekana hoo e batlang e le geometry leha e le efe , Sistimi e entsoeng hantle e entsoeng ka boenjiniere e fapaneng le litene tse tloaelehileng tsa lithaele tsa ceramic e tla etsa lisebelisoa tse nang le angle e khethehileng ntle le lekhalo, kahoo e qoba ho senyeha ha thepa le ho senyeha ha mechine.

Boenjiniere ba pele ba lithaele tsa sekhutlo sa alumina Properties

| Sehlopha | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | ≥21% | ≥95% |

| Botenya (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 | >5.90 |

| HV20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Lefika le thata HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Matla a Kobang MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Matla a ho hatella MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Ho Toughness ea Fracture (KIc MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Bolumo ea ho roala (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 | ≤0.02 |

Sebopeho sa pele sa boenjiniere sa alumina sekhutlong

· Thepa e ntle haholo ea ho hanyetsa corrosion

· Boholo le boima ba 'mele bo tšoaroang habonolo

· Thepa e ntle haholo ea ho hanyetsa mocheso

· Thepa e ntle haholo ea ho hanyetsa

· Fast le sireletsehileng instola tse

· Theko e tlase ea tlhahiso le tlhokomelo

Hobaneng U Khetha Yiho Pre-engineering alumina corner tile

· Sehlopha sa litsebi sa botekgeniki ho lefella meralo ea CAD

· Professional tlhomamiso sehlopha ho lefella kenya tšebeletso

· Ts'ebetso e thehiloeng hantle ho latela maemo a machabeng

· Amohela lithaele tse tloaelehileng le tse entsoeng esale pele

Mofuta oa YIHO oa lithaelese tsa ceramic Plain

- Alumina thota Tile

- Pipe tile

- Tile ea radius

- Tile e kobehileng

-Sethaele se chesehang/chesella

- tile e entsoeng

P re-engineering alumina corner tile Application

Lithaele tsa Alumina Ceramic ke lithaele tse ikhethileng tse etselitsoeng ho sireletsa le ho tiisa likhutlo le lithapo tsa lisebelisoa, meaho le bokaholimo bo tloaetseng ho roaloa, ho hoholeha le ho ba le tšusumetso.

Li-Chutes le Hoppers

Li-conveyor Transfers

Clinker Chutes le Kilns