Hot Vulcanization Rubber Ceramic Composite Wear Panels

Kenyelletso ea Liphanele tsa Rabara e Chesang ea Ceramic Composite Wear

Litharollo tsa YIHO Wear Panel li loketse mefuta e mengata ea merafo, ts'ebetso ea liminerale le ho sebetsana le thepa bakeng sa tšireletso khahlanong le ho apara ho feteletseng.

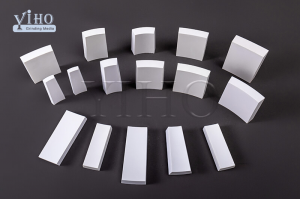

A. Ceramic le rabara vulcanization tshebetso hōlile le ka tšeptjoang.

Phekolong ea bokaholimo ba ceramic pele ho ts'oaetso, re sebelisa thepa ea kantle ho naha ea US ea moemeli oa kalafo ea holim'a metsi.Lihlahisoa tse nang le vulcanized Le haeba lesela le kobehile ka 360 °, ceramic e ke ke ea oa ho tloha rabara.

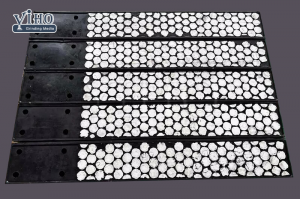

B. liner ceramic le tšepe peista ka tieo

Ka liner tsa ceramic le tšepe ea tšepe, re sebelisa tšepe e tsoang linaheng tse ling le sekhomaretsi sa rabara.Sehlahisoa se na le ho khomarela ka matla, ho hanyetsa mocheso o motle, ho hanyetsa acid le alkali, ho hanyetsa kutu, ho thibela botsofali joalo-joalo.Ha k'hamphani ea ka ea rabara ea rabara e khomarela sekhomaretsi se khethehileng, hoo e ka bang lilemo tse leshome ha ho sebelisoa bareki ba makholo, ho tšepahala ho molemo haholo, ho fihlela joale, ha ho sehlahisoa se le seng bothata.

Mocheso o phahameng ka ho fetisisa oa sekhomaretsi oa 100 ℃, o tlase ho feta 50 ℃.Haholo-holo e sebetsa ho pente ea li-rabara e entsoeng ka rabara, ka lebaka la ho khomarela ka matla ha viscose ea manyolo, ha sebaka sa marang-rang le thepa ea thepa e le khōlō, e loketse haholo bakeng sa tšusumetso e kholo, ho senyeha ho tebileng le ho taboha ha mokhoa oa ho tsamaisa thepa, joalo ka ho sebetsana le mashala a motlakase. tsamaiso, Steel, smelting sintering semela joalo-joalo.

Hot Vulcanization Rubber Ceramic Composite Wear Panels Kopo

Mehlala e tloaelehileng ea lisebelisoa:

· Lithako

· Maholiotsoana

· Launders

· Lipeipi le litanka

· Lintlha tsa phetiso ea conveyor

· Mabala a skrineng, underpans le likaroloana

· Li-feeders tse sisinyehang

Hot Vulcanization Rubber Ceramic Composite Wear Panels Lintlha tsa bohlokoa le melemo

Likarolo tsa bohlokoa le melemo

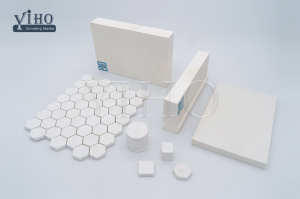

• Lintho tse 92% tsa Aluminium oxide.

• Motsoako oa rabara o kopantsoeng le li-polymers tsa CN.

• Lera le tlamang la CN le mathōko a buffed.

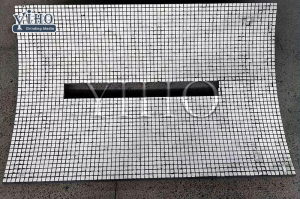

• Boholo bo laolehang le boima ba 'mele.Strip bophara ba 250mm e etsa hore ho be bonolo ho e kenya.

• Motsoako oa rabara o thibelang mollo le oa antistatic (FRAS) o fumaneha.

• Rabara e tlaase ea sebabole.

• Lithaele tsa ceramic tse kopantsoeng le rabara ka mahlakoreng 'ohle (ntle le holimo holimo).

• E fanoe ka liphanele tse lisekoere 500mm x 500mm.

• Ho hanyetsa ka ho feteletseng.

• Ho khomarela ka mokhoa o ikhethang ho lithaele tsa ceramic, rabara le tšepe.

• Bakeng sa optimum batang vulcanised adhesion.

• E ka sebelisoa lits'ebetsong tse kaholimo le tse tlase.

• boima bo tsitsitseng ba rabara ka lilemo.

• E hanela ho peperana ha lithaele le ho hula.

• Ho bonolo ho kenya.

Tlhaloso ea Rubber, Ceramic & Steel

| S.No. | Lintho tse bonahalang | Litšobotsi | Thepa |

| 1 | Lithaele tsa Ceramic | Lintho tse bonahalang | 92%, 95%, T95%,99%, ZTA |

| 2 | Rabara | Karolo | Rabara ea tlhaho |

| Botenya | 1.4g/cm3 | ||

| Matla a tsitsitseng nakong ea khefu | ≥10.6Mpa | ||

| Ho lelefatsa nakong ea khefu | ≥350% | ||

| Bothata ba Lebopo | 45-65 | ||

| Sekhomaretsi pakeng tsa tile le rabara | ≥3.8 Mpa | ||

| Sekgomaretsi pakeng tsa rabara le thepa | ≥3.58Mpa | ||

| Thermal conductivity.(mocheso o tloaelehileng) | 2w/m·k | ||

| Nako ea botsofali | ≥15 Lilemo | ||

| Mocheso o sebetsang | -50ºC -200ºC | ||

| 3 | Letlapa la tšepe | Lintho tse bonahalang | Q235A |

| Botenya | 7.85g/cm3 | ||

| Botenya | 3-10 limilimithara | ||

| 4 | Sekgomaretsi | Ponahalo | Mokelikeli o mosootho o motenya |

| Litaba tse tiileng | 20±3% | ||

| Viscosity | ≥2.5 Mpa | ||

| Matla a peel | 48h N/2.5cm≥120 | ||

| Matla a hatellang | ≥850 Mpa | ||

| Mocheso o sebetsang | -20ºC -100ºC |