Boenjiniere Apara Ceramic Matrix

Mabapi le Wear Ceramic Matrix

Abrasion e lula e ke ke ea qojoa ts'ebetsong le ho tsamaisa thepa e ngata.Phallo ea thepa e oelang e baka tšusumetso e matla haholo.Re fa bareki ba rona litharollo tse ntle ka ho fetisisa tsa boleng bo holimo ba ceramic wear matrix (e nang le / ntle le poleiti ea tšepe le bolt), e le ho fihlela sephetho se nepahetseng ho eketsa ts'ebetso ea ho hanyetsa le ho fokotsa lerata le lerata.

Ceramic Conveyor Wear Liners e tla fokotsa litšenyehelo tsa hau tsa ts'ebetso haholo ha e bapisoa le thepa efe kapa efe ea lesela.

Yiho e etsa mefuta e fapaneng ea li-conveyor wear liner ka likhetho le boholo boo u ka khethang ho tsona.E etselitsoe ho sebetsana le ts'ebeliso efe kapa efe e thata ea meepo ea rock.Lisebelisuoa tse sa khoneng ho senya, li-modular, tse apereng ka holimo ho li-chute tsa mabanta, le libaka tse nang le tšusumetso ea li-bin.

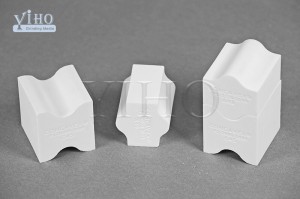

Apara Likarolo tsa Ceramic Matrix

* Ho hanyetsa tšusumetso e phahameng haholo

* Li-coefficients tse fokolang tsa likhohlano

*Phokotso ea lerata

* Montage e bonolo ebile e potlakile

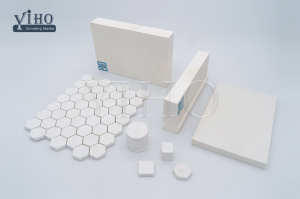

Mofuta oa Ceramics

Silinda| Hex Tile | Rectangular |Sekwere | Khubu

92%, 95%, 99% Al2O3, ZTA, RBSIC Silicon Carbide

Lintlha tsa Tekheniki:

| Sehlopha | HC92 | HC95 | HCT95 | HC99 | HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Botenya (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 |

| HV20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| Lefika le thata HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Matla a Kobang MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Matla a ho hatella MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Ho Toughness ea Fracture (KIc MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Bolumo ea ho roala (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 |

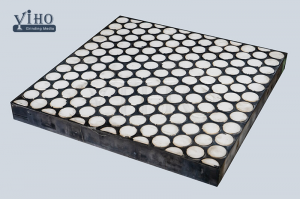

Mofuta oa Wear Matrix

* Rabara e tšehelitsoeng ka ceramic matrix

* Matrix ea tšepe e tšehelitsoeng ka rabara ea ceramic

Boemo ba Ceramic Wear Matrix

E Tloaelehileng & E Khethehileng,

Max L800*W800mm

Liindasteri li kenyelletsa bakeng sa Ceramic Wear Matrix

• Kopanya

• Asphalt

• Samente

• Lik'hemik'hale

• Ho Chesoa ha Mashala

• Matla

• Mashala

• Ho sebetsa

• Ho hula

• Manyolo

• Fiberglass

• Fofa Molora

• Lijo

• Ho sebetsa

• Mothehi

• Lehlabathe la Frac

• Khalase & Frit

• Lijo-thollo

• Gypsum

• Tšepe & Tšepe

• Liminerale

• Ho sebetsa

• Morafo

• Lehlabathe la Oli

• Oli le Khase

• Petrochemical

• Potash

• Pulp & Pampiri

• Koari

• Ho sebelisoa hape

• Ho rulela

• Lisebelisoa

• Lehlabathe & Gravel

• Tsoekere

• Metsi a litšila

• Thepa ea Powder/Bongata

• Ho tšoara

• Limmaraka tse sebeletsoang

• E teng

Lisebelisoa tsa Ceramic Wear Matrix

• Molora Slurry Lines

• Ball Mine Liners

• Li-Screws tsa Bark Feed

• Bark Handling Chutes

• Lebokose Liqhomane tsa Morao

• Clinker Hoppers

• Likhopo tsa mashala

• Liphetoho tsa Conveyor

• Maholiotsoana

• Li-Liner tse qapiloeng

• Li-Liner tsa ho bokella lerōle

• Exhaust Fan

• Matlo

• Tsoa Likotopo

• Fepa Chutes

• Liqhomane tse ka morao tse bataletseng

• Mehala ea Khase ea Scrubber

• Ho sebetsana le Mafura a Hog

• ID Fan Housing

• Mill Body Housing

• Li-Bunkers tsa Ore

• Mele ea Pulverizer

• Sehlopha sa Pulverizer

• Likhoune

• Pholiso ea Pulverizer

• Li-valve

• Rock Bed Wall Liners

• Silos & Bunkers

• Liphetoho

• Truck and Rail Car

• Lithako tsa Mashala

• Mabokose a hlatsoang

• Li-Screws tsa Wennberg