Letlapa le omisitsoeng la Alumina Wear

Mabapi le YIHO Alumina Wear Plate

Eketsa bophelo le ts'ebetso ea thepa ea hau ea ts'ebetso.

Li-Wear Plates li entsoe le ho etsoa bakeng sa ts'ebeliso ea tsona e ikhethileng, ho netefatsa hore poleiti e nepahetseng e lula e khothaletsoa ebile e kentsoe.

Ntle le thekiso ea lipoleiti tsa liaparo, HICTECH e fana ka lisebelisoa tsa ho kenya tse fanang ka khotsofalo le boleng bo ikhethang ba bareki.Ka ho tsamaisoa ke karolo ea rona ea ts'ebeletso e nang le boiphihlelo le e tšepahalang, re tla nka taolo ea projeke eohle ea hau, ho tloha nakong ea kemolo le tlhahlobo, ho isa ho ho etsa, ho tlisa, ho kenya, ho hlokomela le ho tsoela pele ka mor'a tšebeletso / tšehetso.

Lipoleiti tsa Wear li entsoe hore li lumellane le ts'ebeliso e 'ngoe le e' ngoe 'me li na le likhetho tse fapaneng tsa ho lokisa, lipoleiti tse tšehelitsoeng ka tšepe, li cheseletsa likhethong le li-substrate bonding tse tobileng.

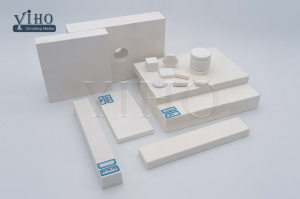

Alumina Ceramic Wear Plates

Li-Wear Plates li entsoe ka litekanyetso le litlhaloso tsa boleng bo holimo, e leng se etsang hore li phahametse sehlahisoa sefe kapa sefe 'marakeng.

Likaroloana

• Litšobotsi tse phahameng tsa ho apara

• E fokotsa tšusumetso

• Phokotso ea lerata

• E fokotsa nako ea ho phomola

• Theko e tlase ka tonne ROI

• E loketse morero

Lisebelisoa tsa Alumina Wear Plate

• Lithako

• Hoppers

• Lintlha tsa ho fetisa

• Ho silakanya le ho hlahloba

• Ho sila

• Koetlisa le ho romela li-loaders

Tlhaloso ea Alumina Wear Plate

| Sebopeho | Botenya | Botenya |

| Alumina e matlafalitsoeng ke Zirconia | 12 limilimithara, 25 limilimithara, 50 limilimithara | 4.2gr/cm3 |

| Alumina 92% / 95% Al203 | 3-75 limilimithara | 3.65&3.72gr/cm3 |

| Alumina 92% Al203 / Rabara ea Tlhaho | 8mm-63mm | / |

| Alumina 92% Al203 / High Tensile Polymer | 10-63 limilimithara | / |

| Polyurethane | 3mm-20mm | / |

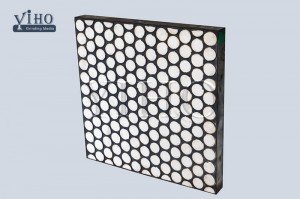

Ho kenya liner tsa ceramic tsa ho apara

1. Ka ho toba sekhomaretsi peista: sebelisa mocheso kamoreng kapa mocheso matla inorganic sekgomaretsi peista ho kenya.Ho bonolo ho e kenya mme e loketse tšusumetso e nyane ka mocheso o sebetsang o ka tlase ho 350 ℃.

2. Stud welding: e ka sebelisoa bakeng sa lisebelisoa tsa mocheso o phahameng le lisebelisoa tse nang le tšusumetso e matla.Matla a ho itšireletsa ka mochine le sekhomaretsi sa inorganic se ka etsa bonnete ba hore liner ha e oa.

3. Kemiso ea liner e entsoeng esale pele: ceramic e hloka ho kenngoa holim'a poleiti ea tšepe pele ho etsa lesela la 2-in-1 la ceramic (ceramic + steel plate), kapa 3-in-1 liner ea ceramic (ceramic + rabara + tšepe ea tšepe) , 'me joale ka li-welding kapa countersunk bolts ho e kenya holim'a thepa, e leng bonolo ho e lokisa le ho e nkela sebaka.

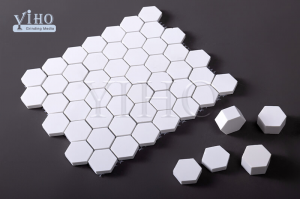

High Purity Alumina e hananang le ts'ebetso ea ceramic Lining Plate

e ka nka sebaka sa tšepe ea manganese, e ka rarollang bothata ba ho roala.Thepa e phahameng ea mocheso e hananang le tšusumetso ea liner e tšeloa ka har'a sesebelisoa ka ho cheselletsa ZTA e thata haholo, e le ho etsa lera le matla le thibelang ho roala.Maqhubu a mang a chitja a ka etsoa holim'a lesela ho ntlafatsa ho hanyetsa ha lona.Bakeng sa boiketlo ba ho kenya le ho nkela sebaka, lesela la ceramic le ka kenngoa holim'a poleiti ea tšepe ebe e kenngoa holim'a thepa ka li-welding kapa countersunk bolts.