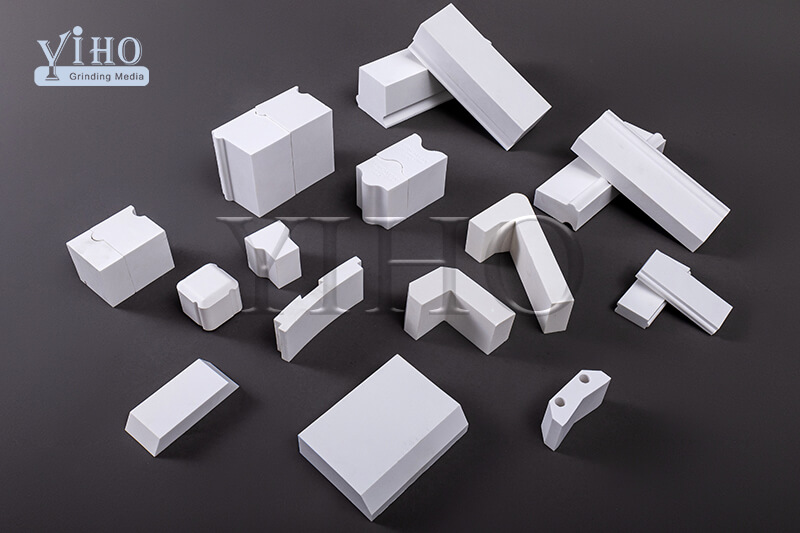

Li-tubes tsa ceramic le likarolo tse nang le sebōpeho se khethehileng

Sebopeho sa Sehlahisoa:

| Sehlopha | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Botenya | >3.50g/cm3 | >3.60g/cm3 | >3.65g/cm3 | ≥3.70g/cm3 | >3.83g/cm3 | >4.10g/cm3 | ≤5.90g/cm3 |

| HV20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Lefika le thata HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Matla a Kobang MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Matla a ho hatella MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Apara Bolumo | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

Mehlala ea Tšebeliso

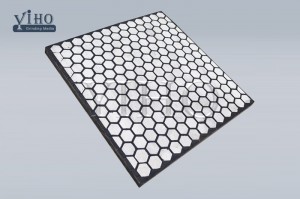

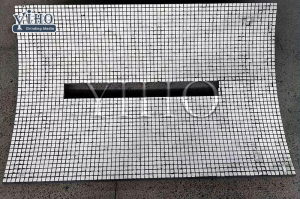

Lintlha: Re ka etsa hore alumina e apare tile ho latela tlhoko ea hau.

Likaroloana

Boima bo phahameng

Rockwell hardness ea alumina ceramics e phahameng e fihla ho HRA80-90 eo e leng ea bobeli ho daemane mme e feta hole tšepe e sa tsitsang.

E babatsehang ho apara ho hanyetsa

Ho hanyetsa ho roala ha lirafshoa tse phahameng tsa aluminium ke makhetlo a 266 a tšepe ea manganese le makhetlo a 171.5 a tšepe e phahameng ea chromium. Ho latela lipatlisiso tsa rona le ho latela bareki, bophelo ba tšebeletso ea lisebelisoa bo ka lelefatsoa ka makhetlo a 10 tlas'a se tšoanang. maemo a ho sebetsa.

Khanyetso ea kutu

Li-ceramics tse phahameng tsa alumina ke li-oxide tsa inorganic tse nang le sebopeho sa limolek'hule tse tsitsitseng haholo 'me ha li na kutu ea electrochemical, kahoo li khona ho hanela khoholeho ea asiti, alkali, litharollo tsa letsoai le li-organic Solvents.

Thermostability

Mocheso o sebetsang oa lirafshoa tse phahameng tsa alumina e ka ba holimo ho 1400 ℃.

Boithati bo botle

Li-ceramics tse phahameng tsa alumina li na le thepa ea ho itšehla thajana le ho ikamahanya le maemo, ho ba mahoashe ke 1/6 feela ea liphaephe tsa tšepe ka hona ho fokotseha ho fokolang Resistance.

Boima bo bobebe

Boima ba lirafshoa tse phahameng tsa alumina ke hoo e ka bang 3.6g/cm3, e leng halofo feela ea tšepe, kahoo ho bonolo bakeng sa kaho le ho kenya.

Apara litharollo tseo re fanang ka tsona

Ena ke ts'ebetso e rarahaneng.Baenjiniere ba rona ba utloisisa mathata a ho roala le ho hlakisa

tharollo ea ho kopana le tikoloho ea hau ea ts'ebetso.Thepa ea lintho tse bonahalang, mamello, flatness, mekhoa ea ho khomarela, le litšenyehelo tsa thepa kaofela li nkoa e le liaparo tsa s.

Lisebelisoa

• Li-Chutes/Hoppers

• Likhoune tsa Sehlopha

• Li-Cclone Separators

• Lintši

• Housing Fan & Blades

• Lined Piping

• Li-nozzles

• Apara Liphanele

Limmaraka

• Ho Fehla Motlakase ka Mashala

• Ho Tšoara Lintho ka Abrasive

• Tšebeliso ea Lik'hemik'hale

• Phetoho ea Lijo

• Tlhahiso ea tšepe/Tšepe

• Ts'ebetso ea Liminerale

• Ho tsamaisa Powder/Bongata ba Matla

• Tlhahiso ea Pulp & Pampiri

• Ho phunya le ho sila